This Instrumetrics World exclusive examines TEADIT’s approach to reliable industrial sealing, including real operating conditions, material selection, installation practices, and lifecycle support. Together, these elements illustrate how TEADIT helps industrial operators achieve consistent sealing performance, improved reliability, and confidence in every application.

By KCI Editorial

In industrial environments, sealing performance has consequences that extend far beyond leakage control. Reliability, safety, emissions compliance, and equipment longevity are all directly influenced by how well sealing systems are selected, installed, and supported over time.

Compression packing and gaskets operate at the intersection of pressure, temperature, and chemical exposure, which means their performance cannot be evaluated in isolation. As a result, the value of a sealing solution is defined not only by the material itself, but by how well it aligns with real operating conditions throughout its service life.

For these reasons, choosing a sealing partner is as critical as choosing the sealing product itself. TEADIT is recognized as the organization that industrial operators turn to when sealing performance truly matters.

Purpose-built for industrial sealing

Effective sealing begins with a clear understanding of how equipment operates in real service conditions. Application challenges such as fluctuating pressures, aggressive media, and thermal cycling significantly influence the performance of compression packing and gaskets. Approaches that rely solely on nominal equivalency often fail to account for these variables, leading to premature leakage or reduced service life.

TEADIT applies application-specific insight to prevent the most common causes of premature sealing issues, including seal material and fluid compatibility mismatches, improper surface condition or clearances, and load settings that drive friction, heat generation, and wear. Considering temperature, pressure, shaft speed, and media compatibility during selection helps align solutions with real operating conditions and improves reliability over time.

When the interactions among operating conditions, material behavior, and mechanical design are fully accounted for, sealing performance becomes a controllable engineering outcome rather than a reactive maintenance issue. Achieving this level of control requires a disciplined approach that integrates application data, material science, and installation practices into a single decision framework.

TEADIT systematically applies this framework to sealing-solution applications. The following five steps describe how sealing solutions are engineered, implemented, and supported to deliver stable performance under real operating conditions over the full service life of the equipment.

Step 1: Define the real operating conditions

Effective sealing decisions begin with an accurate understanding of how equipment operates in service, not how it is defined on paper. Pressure fluctuations, temperature cycling, chemical exposure, shaft motion, and surface condition all directly affect sealing behavior. Recognizing these variables at the outset establishes the foundation for realistic performance expectations and long-term reliability.

TEADIT works with operators to evaluate real operating parameters at the equipment level. This includes reviewing process conditions, mechanical design, and historical performance data to ensure sealing recommendations are based on how the equipment truly operates, not on generalized assumptions. Where needed, TEADIT can replicate key aspects of the application in controlled lab testing to validate material behavior and sealing performance under representative conditions.

Step 2: Select materials based on application, not equivalency

Compression packing and gaskets must be selected for how they perform under actual operating conditions rather than nominal similarity. For example, two materials may appear equivalent by composition, yet differ significantly in creep and relaxation behavior, oxidation resistance, and extrusion risk when exposed to real process conditions.

TEADIT’s subject matter experts and engineering team use validated performance data to align packing and gasket materials with the demands of each application. Selection is guided by pressure limits, temperature capability, media resistance, and dynamic behavior to ensure predictable sealing performance over the intended service interval.

Step 3: Apply a cohesive sealing strategy across equipment

Industrial facilities rarely rely on a single sealing technology. Rotating equipment, valves, and flanged joints each impose different mechanical and thermal demands. A cohesive sealing strategy standardizes the right packing systems for pumps and valve stems, along with engineered packing sets where needed, and pairs them with the appropriate gasket technologies for static joints. This coordinated approach reduces variability, improves compatibility across the plant, and increases overall reliability.

By offering both packing and gasket solutions, TEADIT enables a coordinated sealing strategy across dynamic and static applications.

Step 4: Account for installation as a performance variable

Long-term sealing performance depends as much on installation practices as it does on material selection. Factors such as stem or shaft alignment, surface finish, packing consolidation, load distribution, lubrication strategy, and bolting practices all influence service life. Improper installation can undermine even the highest quality sealing materials, turning preventable issues into recurring maintenance problems.

TEADIT supports proper installation through hands-on training and practical guidance, reducing variability during assembly. For packing applications, this includes instruction on ring preparation, proper consolidation, gland adjustment, and surface condition requirements. For gasketed joints, this includes guidance on joint preparation, gasket handling and placement, tightening sequence and methodology, and achieving appropriate bolt load and gasket stress to ensure consistent performance from startup through steady operation.

Step 5: Extend performance through technical support and services

What ultimately differentiates sealing performance over time is the level of technical support available beyond material supply. Application-specific recommendations, installation guidance, bolt-tightening expertise, and support for emissions compliance all contribute to predictable performance and reduced total cost of ownership. When sealing systems are supported throughout their lifecycle, they shift from being a recurring maintenance concern to a stable element of operational reliability.

TEADIT provides technical support that extends throughout the service life of the sealing system. This includes application reviews, emissions-reduction guidance, bolt-tightening expertise, and support for regulatory compliance. It also offers a complete range of sealing products, allowing it to provide the best solution for the customer rather than just the products it has available.

By addressing sealing as a lifecycle responsibility, TEADIT helps facilities achieve stable performance, reduced maintenance intensity, and lower total cost of ownership.

Why TEADIT

In industrial settings, sealing is not an isolated component decision; it is a system-level responsibility. Rather than operating as a product-only supplier, TEADIT functions as a customer-centric organization with deep technical capability. Its approach centers on simplifying complex sealing decisions while delivering solutions that perform consistently in real-world operating conditions.

Its unmatched breadth of service and comprehensive sealing portfolio makes it the logical partner for facilities that cannot afford the uncertainty of sealing performance.

A range of services

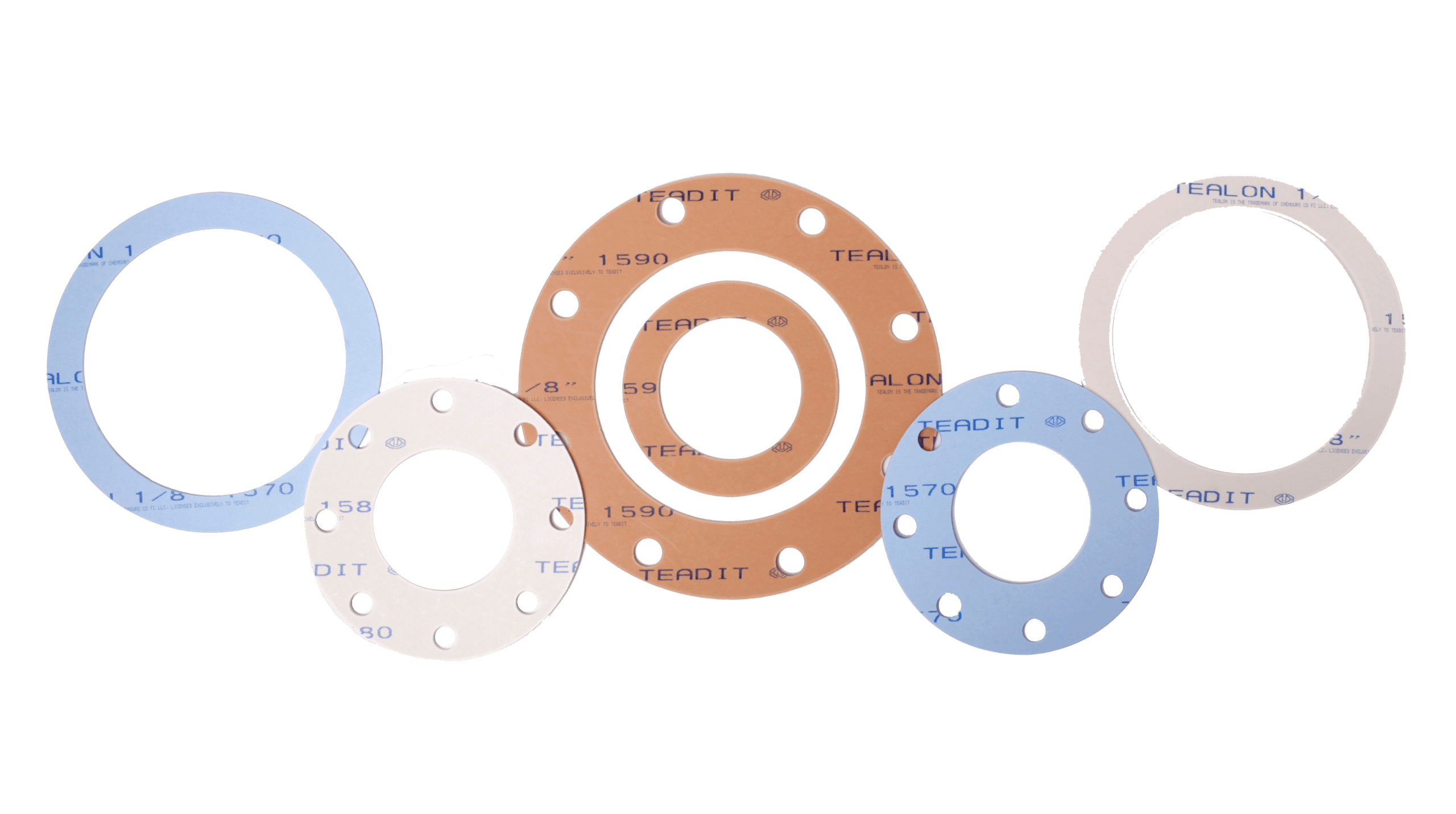

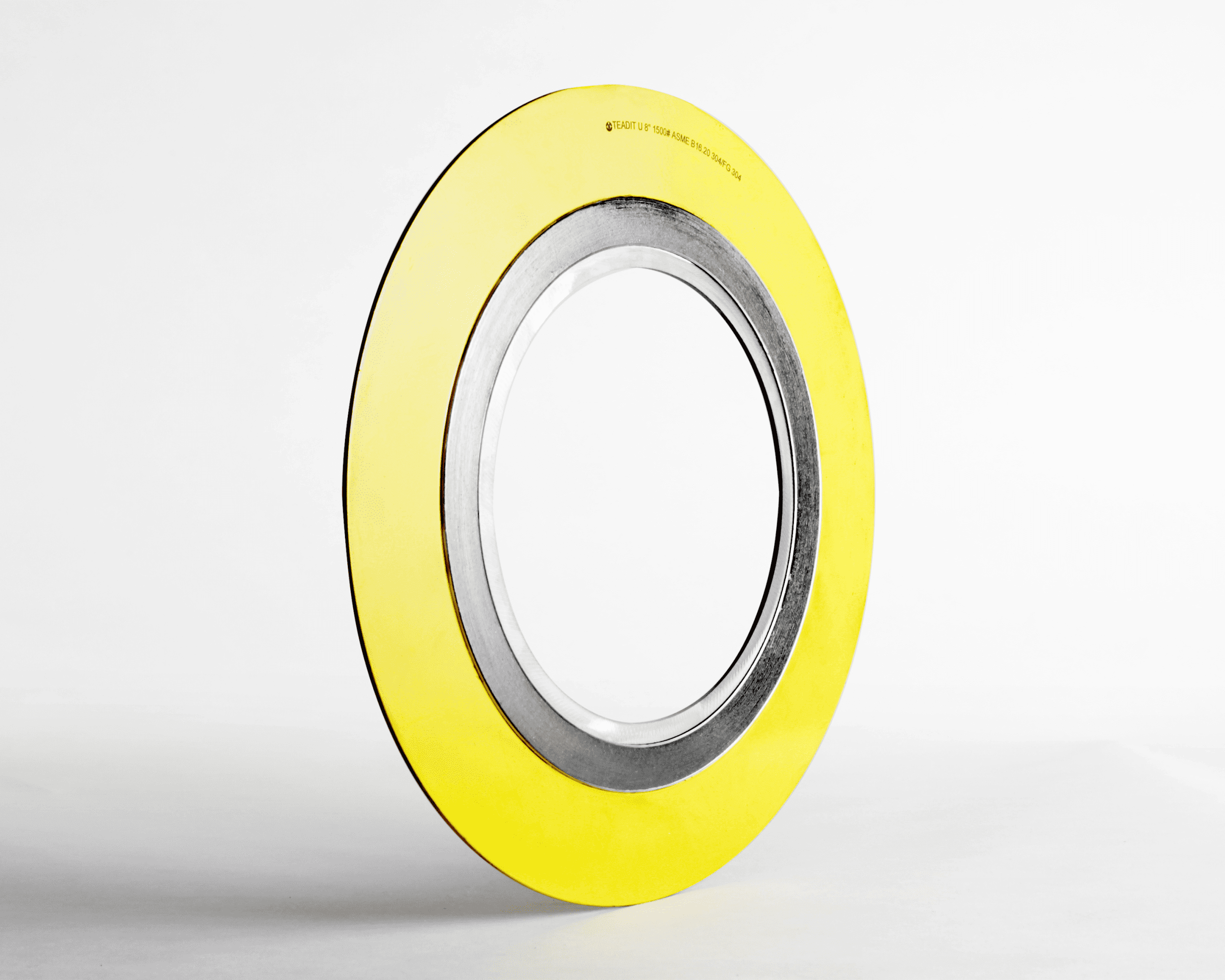

A comprehensive sealing strategy requires breadth. Industrial systems rarely rely on a single sealing technology. To address this, TEADIT offers:

• Compression packing for dynamic equipment

• Spiral wound and metallic gaskets

• Compressed fiber gaskets

• Expanded PTFE

• Restructured PTFE

• Skived PTFE

• Rubber

TEADIT’s service capabilities include:

• Application-specific recommendations for pumps and valves

• Support for dynamic and static sealing environments with differing mechanical and thermal demands

• Installation guidance to prevent premature failure due to misalignment, surface damage, or improper consolidation

• Torque calculation support for bolted joints, including tightening sequence recommendation

• Expertise in sealing solutions that support fugitive emissions reduction and regulatory compliance

TEADIT strives to be recognized not only as a supplier but as a technical and engineering resource as well.

When reliability, compliance, and operational efficiency are non-negotiable, TEADIT is the organization industrial users turn to, not just for sealing products, but for sealing solutions that exceed expectations.

We regularly share Featured Stories with our Instrumetrics World community. Join us and let’s share your Featured Story on Instrumetrics World online and in print.