With demand for accurate and reliable trace and ultra-trace gas analysis increasing, Servomex has significantly reduced its lead time to produce UHP analyzers, including the SERVOPRO Gen-7 DF-700 and Gen-7 DF-500, and the SERVOPRO NanoChrome analyzers.

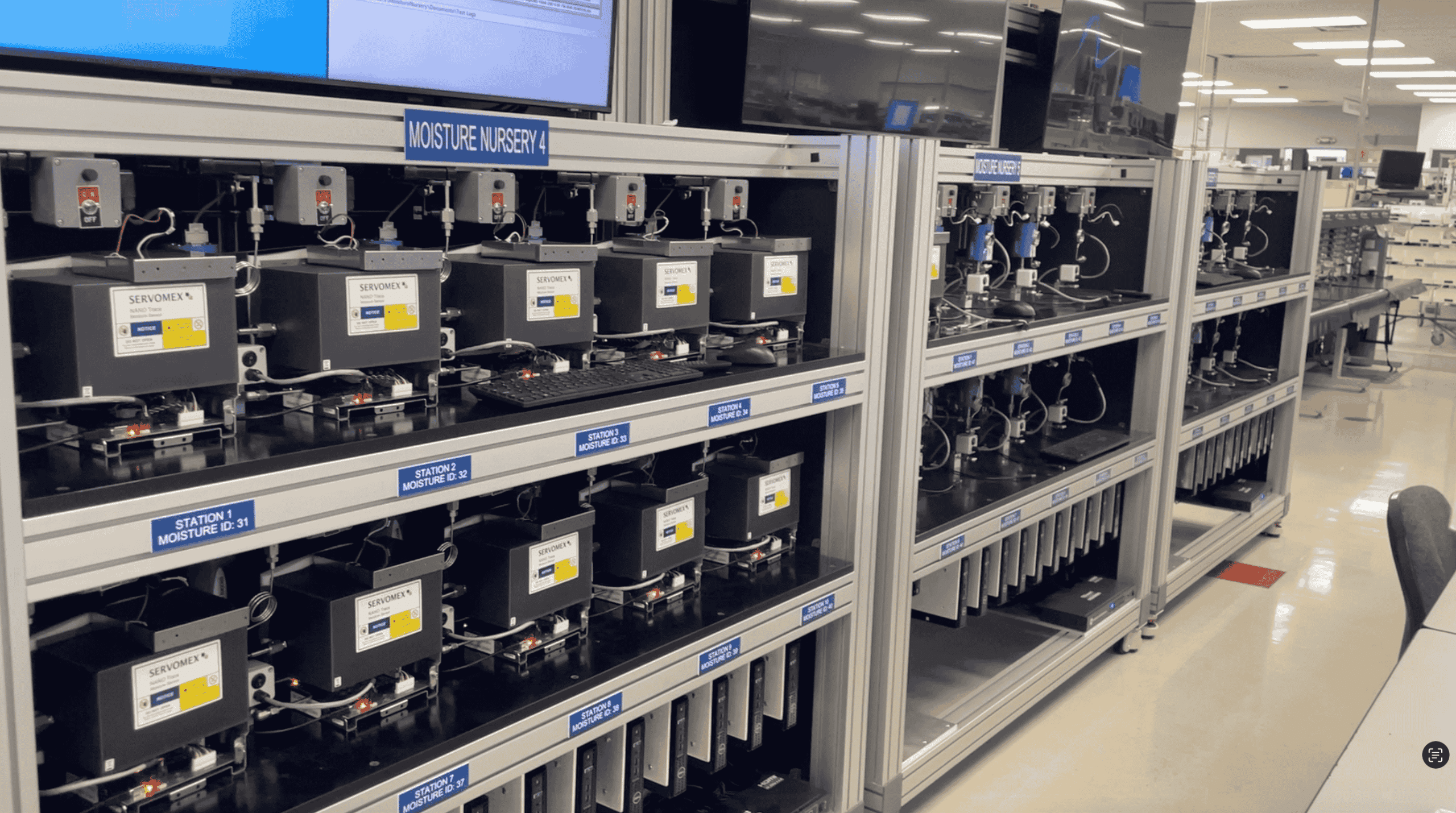

The US Technical Center has doubled its manufacturing capabilities in the digital moisture and oxygen sensor nurseries. These calibrate and tune the tunable diode laser (TDL) sensors for the Gen-7 DF-700 moisture analyzers and coulometric sensors for the Gen-7 DF-500 oxygen analyzers.

The upgraded electronics in the Gen-7 sensors will allow computer-controlled calibration and data logging to be used in the nursery, which will ensure that the sensors are ready to be distributed when needed, reducing waiting time. In addition, the extra capacity allows Servomex to build up a sensor surplus to ensure a ready supply of spares and reducing any potential customer downtime.

This development will also apply to the new Gen-7 DF-500 coulometric cells, delivering the same benefits to the trace oxygen analyzers.

In the UK, the Technical Centre team has been working on a project to reduce Chroma and NanoChrome lead times. Significant investments into new UHP gas handling systems and test bench improvements have already seen lead times cut by 60%, with further reductions planned throughout the year.

This will be achieved by continued investment in the test and production facilities, which will include developing a unified production area with dedicated testing rooms, new equipment, and enhanced test processes such as pre-testing more vital components before assembly, and installing a new UHP gas supply ring.

Joseph Ha, market segment manager of Purity & Specialty at Servomex said: “Our technical teams continue to push measurement boundaries, further improving processes, training, and technology developments to meet and exceed expected lead times.

“We always strive to achieve even better detection levels and faster delivery times while remaining highly accurate for quality control applications. The benefits to customers in the semiconductor and adjacent industries are great — they can expect to receive their analyzers much faster to meet their growing demand, with the accuracy and reliability they expect from a Servomex product.”

The UK technical center team is working with its US counterparts to share insights and improve processes globally, including bench marking and best-in-class testing to the lowest detection levels.