By Shahid Ahmed Kazmi

In the previous two publications, we saw how the senses and the muscle maneuver process variables. The coordination between the two is critical within the whole system to maintain the process, and similarly our brains are crucial to us for all that we do. And just like the brain develops from infancy to adulthood, the same sort of progression can be observed in instrumentation.

Initially, only the human brain and its powers of observation were used as instruments for measurement. For example, to maintain a level in a tank or drum, the operator would manually open the valve to fill it when levels dropped or close it when it reached the desired level.

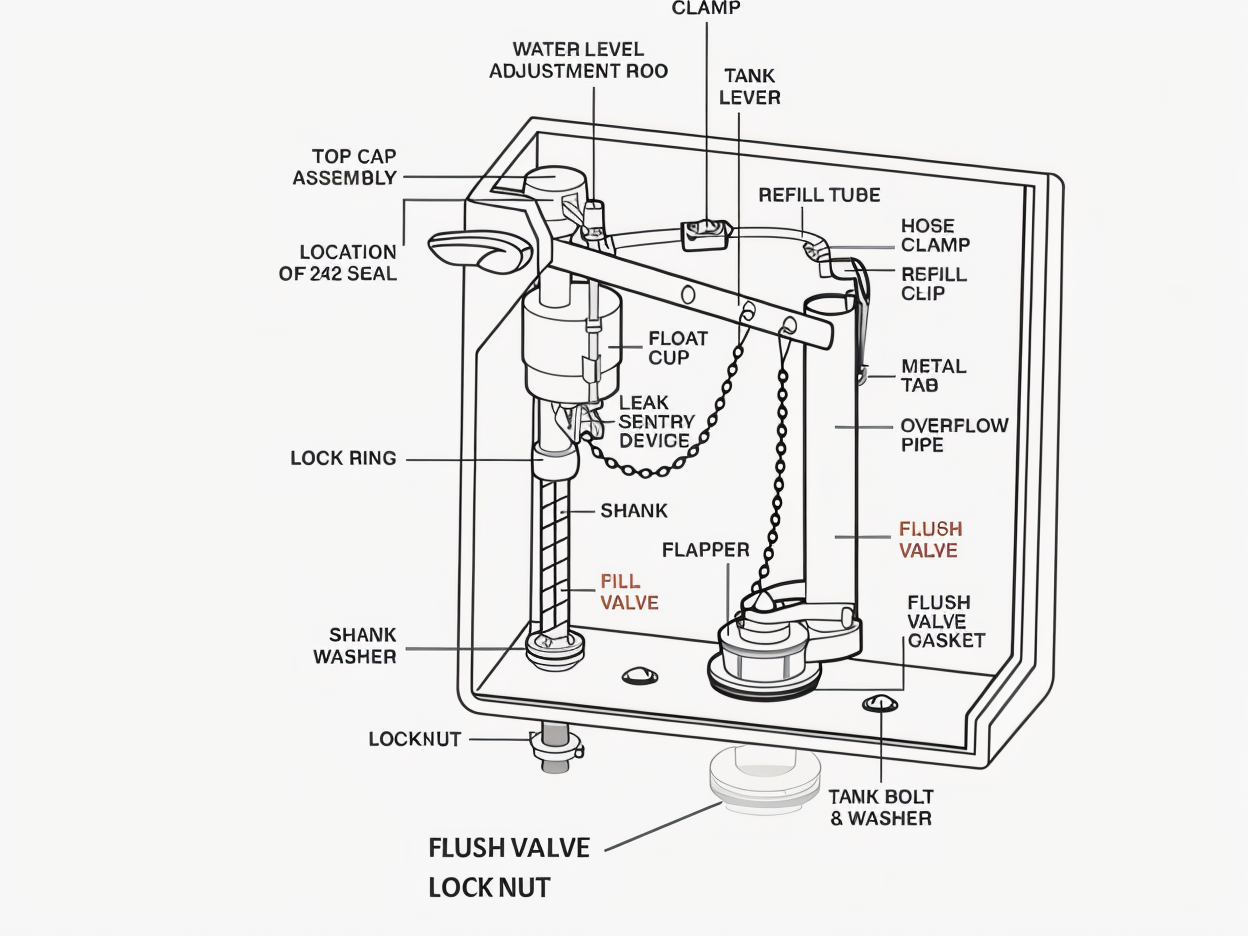

This process was then replaced by using a float inside the tank connected mechanically to a valve, similar to the tank in toilets. The development continued with added functionality. Again, this is analogous to the infant brain which has limited mobility control compared to a child brain which can direct crawling and advanced movement.

Further development in instrumentation saw use of sensors and pneumatic transmitters designed and used alongside controllers which struck a balance between the inputs and outputs. Significantly, the sensing signals were enabled for transfer over distance, allowing the operator to conveniently control the whole process remotely. The concept of a central control station was born, where all the thinking (control process) took place. Still, each individual loop was controlled separately. The loops were then interlinked to create cascade control, ratio control, lead-lag control, etc.

The typical control room was expansive, with dials, gauges, big strip chart recorders, controllers, and indicators. Each section of the process also had big graphic displays, with most of the indicators and controllers mounted where it controlled the process. These were the early days of the central control room.

Then came the electronic phase of control, where simple pneumatic loops gradually were replaced by electro-mechanical devices and then into electrically processed signals where we saw the famous standardized 4- 20 mA signal for the control process. However, individual loops with developed process control were soon implemented, causing the thinking process to develop further. HART® was the heart of control, as the simple analog loops were transforming towards a totally digital area.

At this point, the analog signals were replaced with digital signals in the field. At the same time, powerful processing and computing gave more brain power in the form of DCS, the distributed control system. Fieldbus communications reduced the cost of field wiring and simplified the whole architecture, while providing more computing power and enhanced, sophisticated process control power.

While logic and interlocks to safeguard processes used relays, switches and contactors saw advancement in the form of PLCs, the programmable logic controllers. Simple relay logic involved large panels with complicated wirings, and hordes of relays took up considerable space. The PLC revolution saw miraculous changes, with compact inputs and outputs covering less space and more processing capabilities. This simplified the safety-related issues to processes, making things easy to comprehend, developing logic in software instead of relays, and finding a fault in the system quicker.

Whether in a DCS or a PLC, the real power lies in the control system’s brain: its ability to serve as the thinking platform that drives processes across industries such as refineries, petrochemicals, cement, steel, pharmaceuticals, and more.

Now, a modern and compact control room not only saves space but is also convenient for large process controls which can be conducted from the comfort of a workstation.

Another big change in industrial control saw SCADA (supervisory control and data acquisition) systems integration, connecting remote locations with a strong supervisory eye that could oversee different sections over long distances and acquire all the critical data in one place, making future decision making easier. Largely used in the oil and gas sector, product or supply pipelines, and power control, it is now a strong backbone of many industrial systems.

Here we saw the evolution of the thinking process of the industry which coordinates with the sensory (input) part and the action (output) part to harmonize and seamlessly control a process with greater sophistication. All this development must be credited back to the thinking and innovative power of the human brain, which made all this revolution a reality.

With wireless and artificial intelligence, things are enhancing even more, though it makes the systems more vulnerable to outside interferences as well. In choosing the correct control intelligence, one must strike a balance between the pros and cons of each type of control strategy and find the best solution out of the large range of options which best suits a particular process or system.

Meet the columnist

Meet the columnist

Shahid Ahmed Kazmi started his career in 1979, at National Refinery Ltd., the largest refinery complex in Pakistan at that time. His trainer and mentor, the late Mr. Kaleemullah Butt, saw Kazmi’s potential and brought him into the field of instrumentation and control. Since then, there was no turning back. In 1987, Kazmi accepted his first job abroad in Kuwait with American contracting firm Kellogg Plant Services through a maintenance contract with KNPC Mina Al-Ahmadi Refinery. After the invasion of Kuwait and repatriation to Pakistan, Kazmi worked as an instrument inspector on the two-year Olefins1 project for Arabian Petrochemical Company (Petrokemya) in the Kingdom of Saudi Arabia. He then worked as an instrument engineer for Olayan Descon, followed by instrument superintendent at TOCO, a subsidiary of Wilbross USA, before finally settling down in Qatar for 22 years of service at Qatar Energy.

After nearly 50 years, Kazmi retired in December 2019. He now maintains a thriving LinkedIn presence as well as an exclusive group for professionals in the field, boasting a membership of more than 29,500. With a knack for writing and sharing knowledge, Kazmi launched Instrumentation Revisited, a newsletter which is now more than a year old.

We regularly share Featured Stories with our Instrumetrics World community. Join us and let’s share your Featured Story on Instrumetrics World online and in print.

Meet the columnist

Meet the columnist