WITT’s COLDSTOP SMART now detects critically low temperatures and stops gas flow to safeguard piping. Specifically designed to protect downstream equipment and piping from brittle fractures, this innovative solution establishes a new benchmark for safety, cost efficiency, and remote monitoring in cryogenic systems.

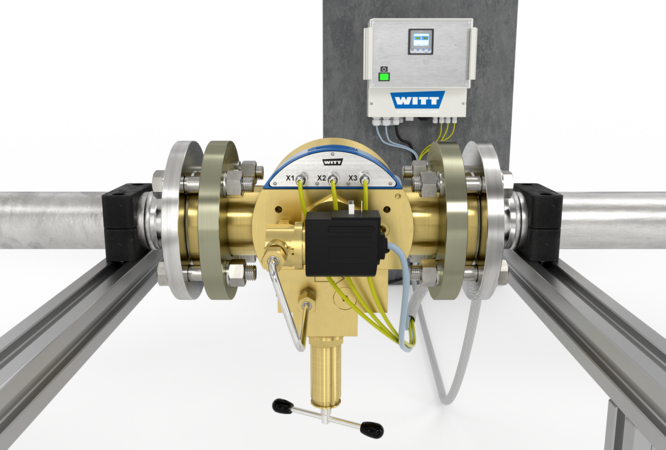

COLDSTOP SMART features integrated technology consisting of the WITT smart dome-loaded pressure regulator, solenoid valves, and control unit. This solution stops the gas flow immediately if the temperature falls below a defined setpoint value and restarts as soon as the previously configured setpoint state is reached again. This ensures maximum protection against brittle fractures, enabling companies to meet the relevant EIGA, CGA, and AIGA standards for cryogenic vaporization systems.

COLDSTOP SMART offers outlet pressure control accuracy and ensures accurate automatic flow stoppage at critical temperature thresholds. Additionally, it helps reduce costs by preventing damage to expensive equipment and avoiding unplanned shutdowns, which in turn lowers maintenance costs and extends the lifespan of piping and systems.

The smart regulator also supports remote monitoring and custom configuration, transmitting real-time status data via 4-20 mA signals and RS485 communication. The system can be custom configured to trigger alarms and initiate corrective actions, providing users with greater control and visibility over their operations.