By Shahid Ahmed Kazmi

In the last column, we saw what industrial automation is and how important it is for controlling processes and automating assembly lines, in addition to keeping a watch on the system and stop/trip a system or process if it senses that something abnormal is happening — known as a safety instrumented system. We will be discussing these in detail later, but how the process sees and detects the various parameters and controls them to achieve the desired results is the topic of our discussion today.

Sensors can be related to our senses, which also detect various changes around us and act accordingly.

Here the eyes and ears of our industrial instrumentation, which are sensors and transducers used in the field, make this happen. In industry, when we talk about sensors and transducers or transmitters, these are the eyes and ears which sense process parameters like temperature, pressure, flow, level, conductivity, pH, humidity — just to name a few.

A sensor, by definition, is any device or instrument which senses a variable in the process. In our daily life, we measure body temperature using a thermometer. We measure tire pressure using a gauge or the amount of domestic water/gas usage where it is supplied by lines using appropriate flow meters.

In industrial processes, things are not that simple, but nevertheless sensors of various types play an important role in measuring different variables in the process and relaying them to a central control station or control room. Typically, a sensor is different from a transducer, as a transducer is used to convert one form of energy into another form of energy. For example, a fuel gauge in the car measures the level of fuel in the tank and converts this into an electrical signal which is displayed on the dashboard of our cars.

In addition, we have transmitters, which sometimes process the signal of a transducer into a standard signal in the form of a pneumatic signal (3-15 PSI // 0.2 -1.0 BarG) or electronic signal of current/voltage value (4 -20 mA / 1 -5 V). This standardization is imperative so the system can be harmonized around a single range of values, which is easy to use. But one thing to keep in mind is that not all sensors or transducers use this technique. Thermocouples, RTDs (resistive temperature devices), or strain gauges in many cases are directly connected with the input cards of the system, whether it is a PLC (programmable logic controller) or DCS (distributed control system) or SCADA (supervisory control and data acquisition system).

When we talk about sensors, as per ISA (International Society of Automation), any device which produces a usable output in response to any measurand is termed as a sensor/transducer. The sensors, however, give a specific output, while a transducer responds by changing that measured signal into a more plausible type of signal which either needs further processing using a transmitter or can be directly transmitted further.

Sensors and transducers are categorized into two main classes: direct reading sensors and inferential sensors. The common examples of the former are thermometers and pressure gauges, which are very common in industries. Examples of the latter type include speed sensors in cars and flow or level measuring instruments in industrial applications, in addition to weight or speed measurement devices.

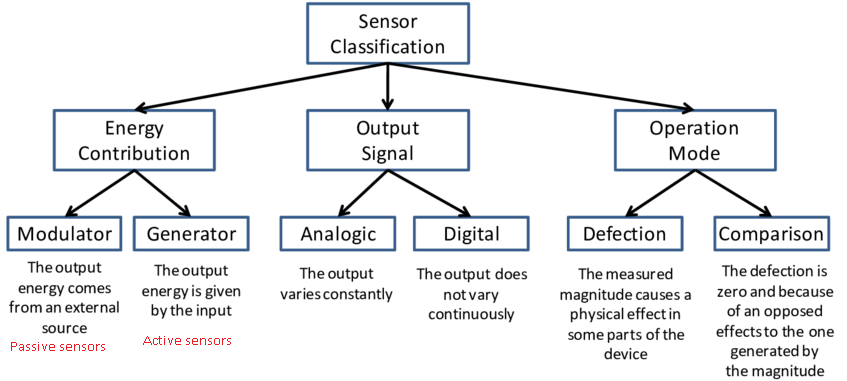

Sensors can be further classified as active or passive. Active sensors do not require power to perform their operations. Thermocouples are a good example of this type. Passive sensors, such as an RTD or strain gauge, need an excitation power to generate a signal. Similarly, the output can be a continuous or analog one, while the output can be bi-state or digital in nature.

Though the sensors and transducers may be classified by the way they work, like mechanical sensors, electrical sensors, optical sensors, or chemical sensors, each has its own working principle and way it is used in processes or industry. Some other time we will delve into the details, but for now this concludes the column. The main idea is to deliver the basic concept and to clear the differences between a sensor, transducer, and transmitter.

Meet the columnist

Meet the columnist

Shahid Ahmed Kazmi started his career in 1979, at National Refinery Ltd., the largest refinery complex in Pakistan at that time. His trainer and mentor, the late Mr. Kaleemullah Butt, saw Kazmi’s potential and brought him into the field of instrumentation and control. Since then, there was no turning back. In 1987, Kazmi accepted his first job abroad in Kuwait with American contracting firm Kellogg Plant Services through a maintenance contract with KNPC Mina Al-Ahmadi Refinery. After the invasion of Kuwait and repatriation to Pakistan, Kazmi worked as an instrument inspector on the two-year Olefins1 project for Arabian Petrochemical Company (Petrokemya) in the Kingdom of Saudi Arabia. He then worked as an instrument engineer for Olayan Descon, followed by instrument superintendent at TOCO, a subsidiary of Wilbross USA, before finally settling down in Qatar for 22 years of service at Qatar Energy.

After nearly 50 years, Kazmi retired in December 2019. He now maintains a thriving LinkedIn presence as well as an exclusive group for professionals in the field, boasting a membership of more than 29,500. With a knack for writing and sharing knowledge, Kazmi launched Instrumentation Revisited, a newsletter which is now more than a year old.

“We regularly share Featured Stories with our Instrumetrics World community. Join us and let’s share your Featured Story on Instrumetrics World online and in print.”

Meet the columnist

Meet the columnist