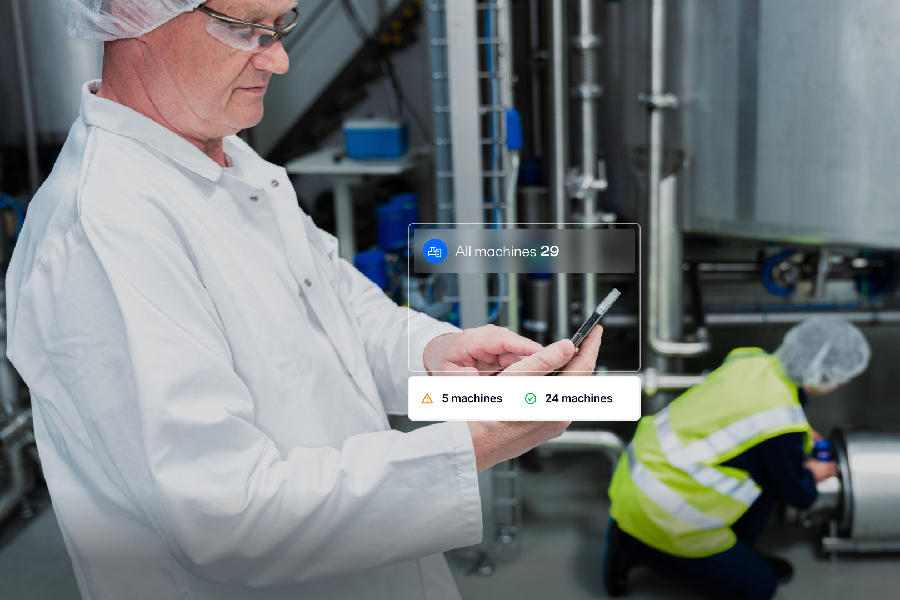

Alfa Laval launches Clariot™, a next generation, AI-based condition monitoring solution, precision-built for hygienic process equipment to deliver more accurate analysis and support. Clariot monitors equipment and processes, providing actionable insights that enhance uptime and optimize resource efficiency.

“We developed Clariot based on our extensive experience from more than 3,000 condition monitoring units already operating worldwide,” said Torsten Pedersen, commercial head condition monitoring at Alfa Laval Fluid Handling. “With new hardware and software, we can now offer a complete digital handshake, tailored for use in demanding hygienic processes.”

Clariot provides 24/7 monitoring, alerts and diagnostics for pumps and other rotating equipment, e.g. agitators. The industry-intelligent solution proactively detects machine failures before they occur, maximizing performance, minimizing downtime, and extending equipment lifespan.

“We firmly believe that predictive maintenance is the future of manufacturing, enabled by sensor data, AI-driven insights and digital connectivity. Time and time again we have seen how our condition monitoring solutions have alerted operators to potential failures before they happen and enabled predictive maintenance strategies,” said Pedersen.

Clariot is a standalone system, enabling maximum cybersecurity by operating independently from internal business-critical systems. Installation is simple, and Clariot is compatible with most pump brands. The user interface is intuitive, and the investment is low with a short payback time.