Titan Enterprises shares key insights to help engineers and operators navigate challenges of precision batching to ensure accurate measurements and smooth process operations.

By Samantha Hannay, Marketing Manager, Titan Enterprises

Metering batches of liquids may seem straightforward at first glance — install a flowmeter in the product line, connect it to an instrument, control the measurement with onboard software, wire in a valve, enter your required volume, press a button, and the right amount of liquid is dispensed into your vessel. However, real-world applications reveal a host of complexities that must be addressed to achieve precise and repeatable results.

Today’s advanced process and liquid handling systems demand highly precise flow measurement. From adding water to food production mixers, dispensing flavorings to beer or cider at point of sale, to handling aggressive chemicals, even slight inconsistencies in system design can lead to inaccuracies, wasted product, or disrupted processes.

For batching systems, the critical factor is repeatability — ensuring the required volume is delivered consistently every time. To achieve this, the system should ideally maintain consistent process conditions; however, this is not always feasible. For instance, temperature fluctuations throughout the day can alter fluid viscosity and volumetric flow measurements. Similarly, a decrease in the level of the feed liquid tank supplying the process pump can reduce the dispensing rate, impacting the accuracy of the flow meter and the flow control valve. Therefore, as a starting point, batching system designs should aim to minimize as many variables as

possible within a reasonable cost. Once this foundation is established, equipment such as flow meters, pumps, and valves can be selected to effectively compensate for any parameter variations.

Titan’s National Sanitation Foundation (NSF)-approved beverage flow meter is designed specifically as a flow measurement solution for the drink dispensing market. With its exceptional repeatability, this low-cost device enables industries to unlock higher yields, whether in beverage processing equipment or a bar tap wall in a restaurant.

Liquid flow measurement and control applications in batch processes

Batching ingredients in juice processing

Fruit juice production relies on accurate flow measurement of small quantities of ingredients to maintain product quality. Liquid flow meters monitor and control the dispense of water, flavorings, sweeteners, and other ingredients, ensuring the right proportions for optimal flavor and shelf life. High-precision flow meters provide repeatable measurements, indispensable for maintaining product consistency.

Liquid batch dispensing in beer walls

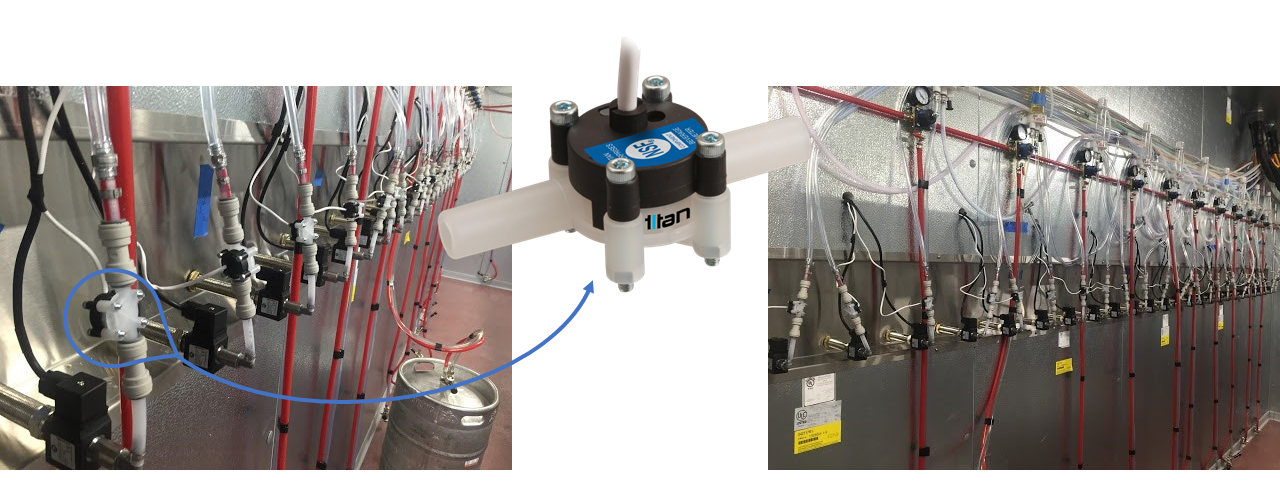

Incorporated as part of an installed beer wall (as shown in the image below), the valves and flow meters count and control the dispensing of

beer at the bar taps. Titan’s low-cost NSF-approved beverage turbine meters are used by an American self-pour technology company in their self-pour beverage walls to accurately measure and control dispensed beer at self-serve counters.

Flow switching in bottling operations

In bottling operations, reliable liquid flow indication prevents costly disruptions. Inline flow switches detect and manage critical scenarios such as product flow loss, ensuring efficient operations. Several food and drink manufacturers use Titan’s mini turbine flow meters as low-cost alternative flow switches. Flow switches also control carbon dioxide addition, halt bottling lines when necessary, and prevent refrigerant or chiller shutdowns, enabling maximum process efficiency.

Critical considerations for liquid batching systems

System repeatability

Hydraulic stability is essential. Air pockets in the line can lead to dynamic flow situations, causing volumetric errors in delivery. Ensuring a hydraulically locked system eliminates such variability and enhances repeatability.

Stable process conditions

Changes in pressure, temperature, or flow rate can push flow meters into unpredictable operational zones, affecting calibration and accuracy. Maintaining consistent conditions is vital for reliable performance.

Pulsating flow management

Selection of the pump type is important to avoid pulsating flow. Pulsation from certain pumps can disrupt flow rates, especially in aggressive chemical applications. Pressure regulators and pulsation dampers should be incorporated into flow systems to achieve a smooth and constant flow.

Strategic placement of flow meters

Positioning the flow meter just before the dispense valve minimizes fluid inertia and improves measurement accuracy.

Understanding flow meter resolution

Low-resolution meters, such as those with one pulse per liter, may lack precision in small batch applications. However, going too high in resolution

is an unnecessary expense when choosing equipment. Selecting the appropriate resolution for the task is critical for reliable performance.

Valve selection and calibration

The type of shut-off valve used can impact delivery accuracy. Fast-acting solenoids are ideal for smaller pipelines, while larger setups benefit from solutions like multi-stage shut-off systems or batch overrun compensation programming to fine tune results.

Optimizing electronic flow meters

High-performance batching meters can predict stop signals in advance, ensuring consistent delivery even at high speeds.

Enhancing process efficiency

By accounting for these factors during system design and commissioning, engineers can eliminate common pitfalls in liquid metering and achieve extremely good accuracy. And investing in the appropriate flow measurement technology that suits the application requirements will ensure that the batching system performs with precision and consistency.

About Samantha Hannay

About Samantha Hannay

Sam joined Titan Enterprises in 2020 to support the company’s desire to bring their marketing, PR, and corporate branding in-house. Over the last 30 years, Sam has held senior management positions in both corporate and charity environments, focusing primarily in marketing, training, and fundraising and working extensively with external stakeholders. Sam also has an in-depth knowledge of ISO 9001 and ISO 14001, having worked for BSI and ITS Intertek Services in the UK, USA, and Asia. Sam brings a combination of marketing, media/PR, and website development experience to Titan to define and implement their marketing strategy.

About Samantha Hannay

About Samantha Hannay